November 10, 2025 in Advisory Notes

Mandatory Climate Reporting and the Role of Buildings

Mandatory climate-related risk and opportunity reporting is a new Australian regulatory requirement for large companies to disclose how climate change...

December 1, 2025

Effectively managing humidity has become essential — not only for occupant comfort and indoor air quality but also for protecting the longevity and value of building assets.

Many commercial buildings continue to face persistent humidity problems due to incomplete HVAC system commissioning, inadequate maintenance practices, or misunderstandings around ventilation control requirements. Without targeted and proactive strategies, minor humidity issues can quickly escalate, leading to costly remediation, tenant dissatisfaction and reputational impacts.

Successfully addressing humidity requires coordinated and strategic collaboration among building owners, facility managers, HVAC specialists and occupants. In a similar way to building system tuning, robust humidity management practices support sustainability objectives, NABERS Indoor Environment ratings and Green Star certification efforts.

The risks of doing nothing are significant:

Even short periods of unmanaged humidity can create long‑term issues for both building performance and asset value.

Many HVAC systems have the inherent capability to manage indoor humidity effectively, yet this potential often remains underutilised due to insufficient commissioning or system tuning.

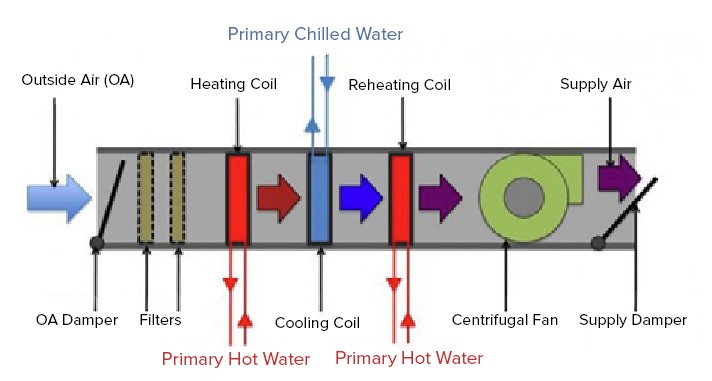

Regularly reviewing and optimising chilled water setpoints, supply air temperatures and reheat strategies against benchmarks ensures your HVAC system can effectively control humidity levels. Incorporating these reviews into seasonal maintenance schedules provides ongoing comfort and energy performance benefits.

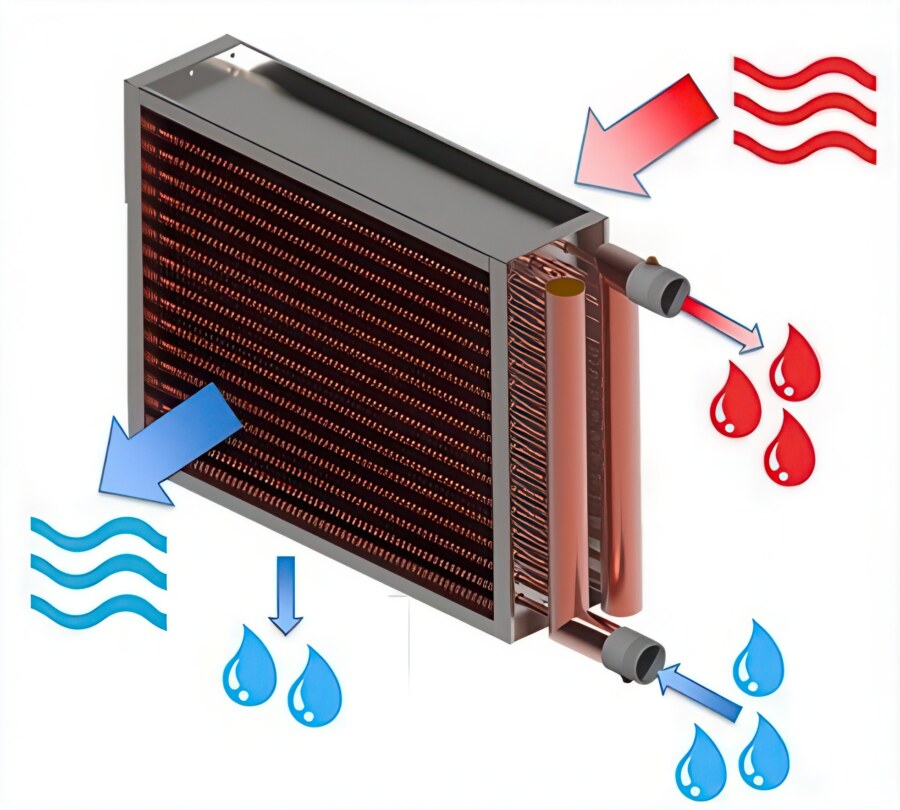

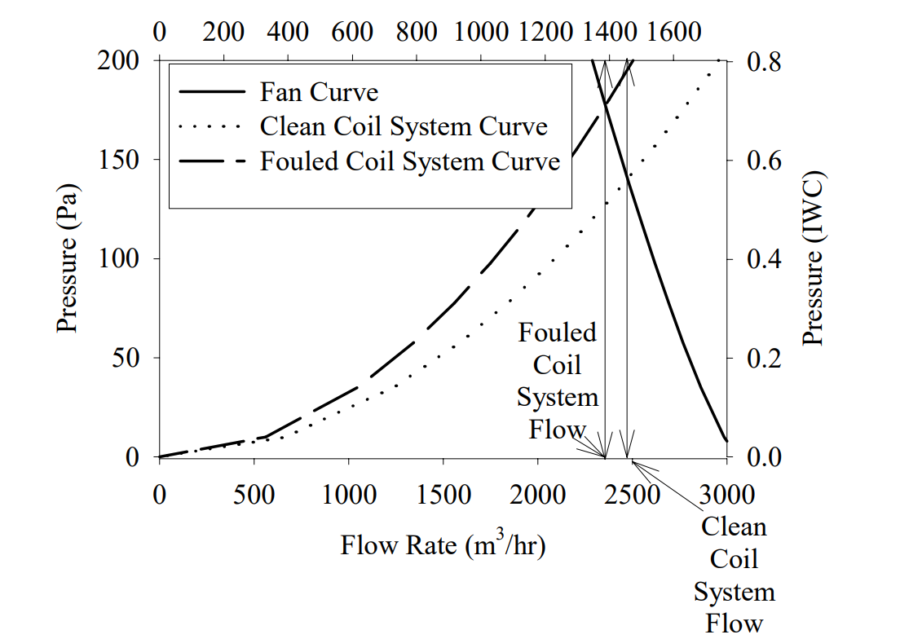

As buildings operate, age and conditions shift, air handling units (AHU) can change from original design intent. Air filters load up and are replaced, sometimes with different media, cooling coils can become partially obstructed, fan speeds get adjusted, or air and water balancing slips over time. None of these issues seem dramatic on their own, but together they change air velocity and coil temperatures — and that can reduce the AHU’s ability to remove moisture and reduce the air’s latent heat load.

A good first step is to review how the AHU is performing today. Understanding current airflows, coil condition and air-off temperatures against the original design helps reveal whether the unit is still providing the level of dehumidification (also known as latent cooling) the building needs.

From there, a few targeted corrective actions can make a substantial difference:

To keep performance on track, a full check and recommissioning of the AHU every five years is recommended. This resets the AHU to its design operating conditions, verifies airflow and balancing and ensures

moisture-removal performance is maintained through the most humid periods of the year.

Regular recommissioning not only stabilises humidity control — it protects finishes, supports energy efficiency and helps the overall HVAC system operate reliably and as intended.

In many HVAC systems these dampers modulate to allow greater amounts of outside air into the system when outside air conditions are favourable.

As such outside air dampers can play a critical role in controlling the volume of humid air entering your building. Without proper inspections, testing and maintenance, these dampers can inadvertently admit excessive outside air when conditions are less than favourable, raising internal moisture levels.

Routine damper inspections and adherence to ventilation standards, such as Australian Standard AS/NZS 1668.2, are important in preventing unintended moisture infiltration.

Additionally, some HVAC systems monitor internal CO₂ levels to help control how much fresh outside air is drawn into the system. Ensure that CO₂ sensors are regularly calibrated and maintained. Incorrect sensor readings can trigger unnecessary outside air intake, increasing indoor humidity levels. Accurate, calibrated sensors reduce this risk, improving both comfort and efficiency.

Maintaining a slight positive internal pressure is one of the most effective ways to prevent humid air from infiltrating through gaps, risers, and doorways. When buildings become negatively pressurised — often from unbalanced supply and exhaust airflows — moist outdoor air is continuously drawn inside, leading to condensation and mould.

To reduce this risk, it is recommended the following actions are undertaken:

Where possible, employ enthalpy-based economy control rather than temperature-only systems. Enthalpy control measures both the heat and moisture content of air, limiting outdoor-air intake on humid days while still enabling free cooling when conditions are suitable.

Continuous monitoring is important for catching humidity issues early. Tracking supply-air humidity, cooling coil air-off temperatures, and internal humidity on a floor-by-floor basis will provide a clear picture of how well the system is actually removing moisture, both at the AHU and in the

occupied space.

Modern BMCS platforms can add significant value to this monitoring data

by applying rules-based algorithms to detect patterns — such as coil performance dropping, outdoor-air dampers drifting, or zone humidity rising despite cooling — and trigger smart alarms that alert operators before conditions escalate.

Strategically placed sensors around coils, drains, ductwork and key floor areas can support this, providing the system with additional data to identify issues early and accurately.

With intelligent analytics and targeted alarms, buildings can respond to humidity problems proactively instead of reacting after mould, condensation or energy waste has already occurred.

Tenants and service providers can play an important role in managing humidity day to day. Simple observations — musty odours, visible condensation, damp spots, or unusual comfort complaints — often provide the earliest signs that something isn’t quite right. Encouraging occupants to report these issues promptly helps prevent small problems becoming major remediation works.

It’s also important that cleaning and maintenance teams understand the impact of their activities. Blocking air paths with equipment, closing grilles,

or disabling ventilation systems during after-hours work can all upset airflow and pressurisation, allowing humid air to infiltrate the building. Clear communication and basic awareness training go a long way in keeping the system operating as intended.

By involving building users and service providers, facility teams gain an extra layer of early detection and support — strengthening the overall

humidity-management strategy.

Humidity initiatives often fail due to:

To stay ahead of humidity risks:

Taking a proactive approach to humidity control is not optional — it’s part of responsible, future-focused building management. The buildings that perform best are those that treat humidity as a core operating parameter, not a seasonal nuisance. With the right combination of tuning, recommissioning, sound ventilation strategies and analytics, buildings can stay comfortable, resilient and energy-efficient even as climate conditions continue to change.

A.G. Coombs Advisory is available to support building owners and facility teams who want to strengthen their humidity-management approach

and safeguard long-term asset performance.

For further guidance on Combating High Humidity in Commercial Buildings, please contact:

Michael Kettle

Senior Technical Specialist

A.G. Coombs Advisory

+61 458 771 598

mkettle@agcoombs.com.au

Loading ratings...

November 10, 2025 in Advisory Notes

Mandatory climate-related risk and opportunity reporting is a new Australian regulatory requirement for large companies to disclose how climate change...

October 8, 2025 in Advisory Notes

Electrification projects can be complex undertakings bringing together a range of technical elements along with planning, coordination and logistics c...

September 1, 2025 in Advisory Notes

Cyber security incidents reported against both government and private organisations continue to increase in both frequency and severity.

July 15, 2025 in Advisory Notes

During COVID-19 many buildings experienced a significant reduction in the number of occupants. With the move to remote working, the reliance on tenant...